Die Casting

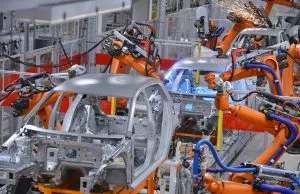

Die casting is an efficient method of forming metal parts in dies, also called tools, which consists of two halves where molten steel or a type of metal is inserted into the cavities to mold metal parts. Die casting is used to produce parts for many industries, with an efficient method of changing dies required for all applications, particularly in automotive manufacturing where continual improvement in product quality and process efficiency is demanded. Stucchi offers hydraulic solutions which help die casting processes significantly reduce time required for tool changeovers, also called exchange of dies, with leak-free quick couplers and multi-coupling plates. Our die casting hydraulic solutions increase equipment uptime and improve process efficiencies

Showing 1–24 of 28 results

-

A-HD SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000 -

A-PREMIER INTERNATIONAL SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000, 5000-9000 -

A-PREMIER SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000, 5000-9000 -

A-ZN SERIES

Contact Us for Pricing InformationProduct Port Options NPTProduct Valve Style Flat Face -

APM SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000 -

BM3 PLATE SERIES

Contact Us for Pricing InformationProduct Body Size 1 1/2"Product Material CarbonProduct Port Size 1 1/2"Product Valve Style Flat FaceProduct Working Pressure Up to 5000 -

DP PLATE SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000 -

FAP FAPZ SERIES

Contact Us for Pricing Information -

FIRG SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000 -

FIRGQ SERIES – QPQ PLATING

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000 -

FL SERIES

Contact Us for Pricing InformationProduct Material StainlessProduct Valve Style Flat FaceProduct Working Pressure Up to 5000 -

GR PLATE SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000 -

GRE PLATE SERIES

Contact Us for Pricing InformationProduct Material BrassProduct Valve Style Flat FaceProduct Working Pressure Below 350 -

Handles and Connectors

Contact Us for Pricing Information -

ONE POSITION PLATE SERIES

Contact Us for Pricing InformationProduct Body Size 1 1/2"Product Material CarbonProduct Port Size 1 1/2"Product Valve Style Flat FaceProduct Working Pressure Up to 5000 -

PPC Series

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000 -

SV2 PLATE SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure Up to 5000 -

VD SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style PoppetProduct Working Pressure Up to 5000 -

VEP SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure 5000-9000 -

VEPHD SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure 5000-9000 -

VEPHDL SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style Flat FaceProduct Working Pressure 5000-9000 -

VLS SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style PoppetProduct Working Pressure Up to 5000 -

VOF SERIES

Contact Us for Pricing InformationProduct Material CarbonProduct Valve Style PoppetProduct Working Pressure Up to 5000 -

VOFX SERIES

Contact Us for Pricing InformationProduct Material StainlessProduct Valve Style PoppetProduct Working Pressure Up to 5000

Stucchi offers hydraulic solutions to many industries and applications, including the diecasting industry or multiple hydraulic quick coupling connections are required. Stucchi’s hydraulic solutions improve diecasting tool changeover times, also referred to as single-minute exchange of dies, or SMED. The time it takes to switch dies between production runs and die maintenance is a key indicator of performance, with companies continually looking to reduce tool changeover times.

The die changeover process involves disconnecting dies from their current heating and cooling lines or occasionally hydraulic lines, removing the die from the press, placing the new die in the press, and reconnecting all lines with the new tool ready to run in the press.

Challenges and Consequences of the Diecasting Quick Coupler Process

Diecasting complex parts with challenging geometries requires a complex tool and depending on the size and complexity of the part, the number of lines to connect for each tool can vary from 2 to 100 lines per die. Due to the large number of connections to be made and the time pressure to changeover as quickly as possible, hooking up lines incorrectly can be a real concern for diecasting operators, which could have serious consequences.

Producing parts out of spec, that must be either reworked or scrapped, is a big waste of material and press time. Depending on the parts produced, several bad parts could be run before a problem is identified. This can lead to thousands of dollars in scrap product, labor for rework, and press downtime which can be thousands of dollars per hour.

Stucchi’s Die Casting Solutions

Stucchi offers quick connect solutions that add value to the die casters with improved diecasting change over time that help companies achieve SMED goals. Some of our quick connect products proven to help the diecasting process include:

DP/GR/GRE Multi-Coupling Plate Series – multi-coupling plates allow for the simultaneous quick connect and disconnect of multiple lines at once without the risk of crossmatching lines.

VEP threaded flush face couplings – Stucchi’s VEP series of flat face couplers allow for easy connection of large-size hydraulic lines

FIRG-Q push to connect flat face couplers – quick push to connect solutions for heating and cooling mediums

Stucchi has provided significant improvement in tooling changeover times, such as highlighted in this Case Study on Productivity, where the GRE series multi-coupling plate shaved a full six minutes off of exchange of dies time for one tier two automotive manufacturer.

Watch this VIDEO on How to Improve Die Changeover Time in Die Casting

Stucchi offers quick connect solutions to improve tool changeover times, improve operational efficiencies and inventory turns, and help manufacturers to increase capacity with greater efficiency and press utilization.

Diecasting is the preferred manufacturing method for many industries and applications, creating steel or metal parts efficiently with consistent quality. Some industries which utilize diecasting parts include:

Diecasting is the preferred manufacturing method for many industries and applications, creating steel or metal parts efficiently with consistent quality. Some industries which utilize diecasting parts include:

- Automotive

- Aerospace

- Firearms in defense

- Consumer goods

- Electronics

- Complex machinery and equipment

- Toys

Die casting provides high-quality products for these industries and many others, with product quality delivered with complex tooling (dies) that mass-produce complex parts with high quality, consistently and efficiently. Manufacturers make money when presses are running parts, and unscheduled downtime is money wasted and an opportunity for improvement. Stucchi offers quick connect solutions to improve efficiency and press utilization with quicker tool changeover times as well as faster scheduled maintenance.

Stucchi offers hydraulic solutions to a broad range of industries and applications with more than 60 years of experience in a team of highly skilled hydraulic experts. We offer expertise in many market applications, including die casting and tool changeovers. Contact us to learn more about improving your tool changeover time and meeting SMED goals with Stucchi’s hydraulic solutions for the diecasting industry.